so we just got the turbo Pontiac put together and rolling, but can't figure out why it goes completely lean after getting full boost for a couple seconds

the combo: 408 Pontiac, 8.3:1, cleaned up 6x heads, arp bolts, single plane, old 750dp, holley hp150, Mallory boost reference FPR, 3/8 feed 1/2 return fuel lines, HEI ignition locked at 20 degrees, GT45 ebay turbo 69mm, homemade passenger side crossover manifold to turbo flange, 4" inlet tubing with a spectre hat, 50mm ebay BOV, 38mm godspeed wastegate.

boost reference for FPR and wastegate is plumbed from the carb hat, bov from manifold.

put floats in carb, sealed choke, drilled pvcr to .059 from the factory .040, jets are now at 66 and 86. vent tubes extended into inlet.

So, If I roll onto it, it is still showing low 10's A/F until it sees full boost (about 8psi) where it settles about 10.9:1. using innovate wideband. part throttle is now acting ok in the mid 12's range.

I stuck a gauge to my windshield and the fuel pressure seems to reference 1:1. I had it set at 6psi and it jumped to 15ish under 8-9psi of boost.

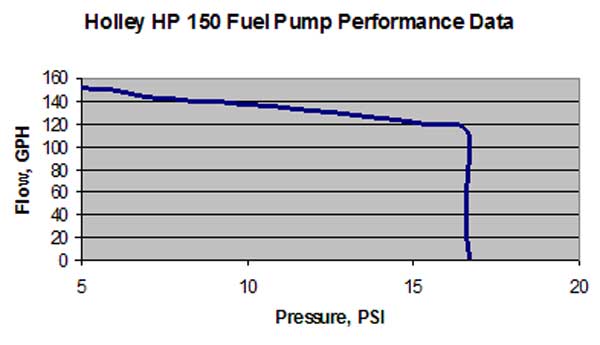

here's my issue. after it kicks ass for a couple seconds, the A/F drops out to lean almost instantly. i'm talking not even 1/8th mile from a dead stop. the only things I can think of is #1, the .110 needle and seats are holding me up, or #2 the pressure above the carb is higher than the 16psi max of my fuel pump.

I ordered .120 needle and seats, but apart from that i'm stumped. any insight from those in the know? drag week registration is sunday! thanks in advance!

the combo: 408 Pontiac, 8.3:1, cleaned up 6x heads, arp bolts, single plane, old 750dp, holley hp150, Mallory boost reference FPR, 3/8 feed 1/2 return fuel lines, HEI ignition locked at 20 degrees, GT45 ebay turbo 69mm, homemade passenger side crossover manifold to turbo flange, 4" inlet tubing with a spectre hat, 50mm ebay BOV, 38mm godspeed wastegate.

boost reference for FPR and wastegate is plumbed from the carb hat, bov from manifold.

put floats in carb, sealed choke, drilled pvcr to .059 from the factory .040, jets are now at 66 and 86. vent tubes extended into inlet.

So, If I roll onto it, it is still showing low 10's A/F until it sees full boost (about 8psi) where it settles about 10.9:1. using innovate wideband. part throttle is now acting ok in the mid 12's range.

I stuck a gauge to my windshield and the fuel pressure seems to reference 1:1. I had it set at 6psi and it jumped to 15ish under 8-9psi of boost.

here's my issue. after it kicks ass for a couple seconds, the A/F drops out to lean almost instantly. i'm talking not even 1/8th mile from a dead stop. the only things I can think of is #1, the .110 needle and seats are holding me up, or #2 the pressure above the carb is higher than the 16psi max of my fuel pump.

I ordered .120 needle and seats, but apart from that i'm stumped. any insight from those in the know? drag week registration is sunday! thanks in advance!

Comment