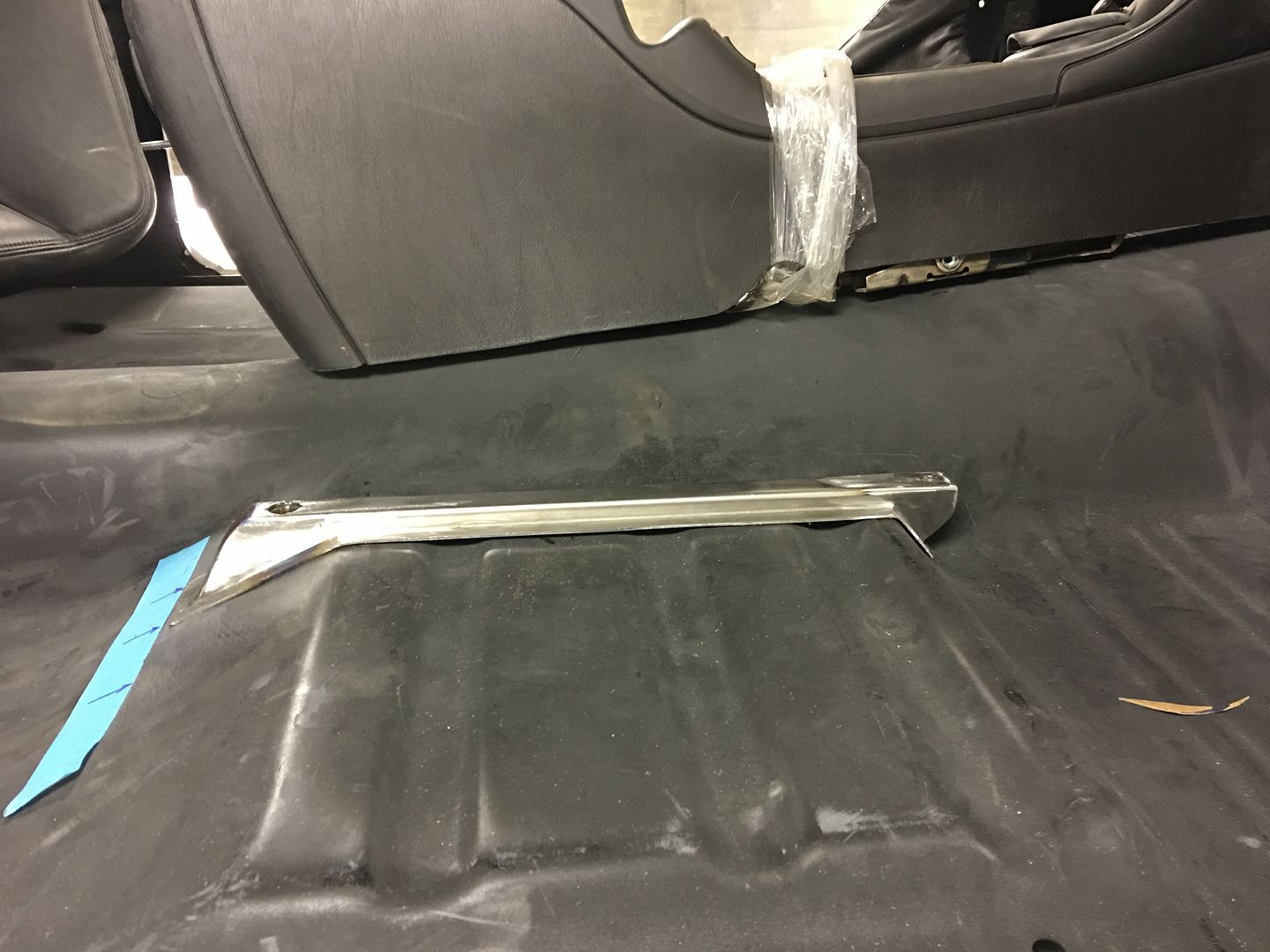

That makes sense, more than likely not worth the trouble, but you could put the inside on the floor, a little riser on the lower side then spacers between the seat and the track.

But it's hard to go wrong with sag!

But it's hard to go wrong with sag!

Comment