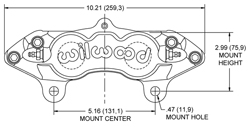

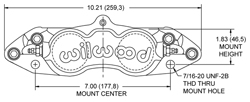

I have a question about the C3 (Corvette) system. It is beyond my pay grade to understand why the front (which operates the front brakes) brake line from the booster to the proportioning valve is smaller to the front wheels than it is to the rear. I intend (unless some explains to me prior) to change the lines to the proportioning valve to same size (and let the valve, not the pipe size change the amount of fluid the front brakes get).

I think someone made a mistake at SS brakes because the front line/rear line orientation on a C3 is reversed of what is "normal." Normally, the front reservoir feeds the front brakes, and the rear the rear brakes; but on a true C3 Master cylinder the line from the front then crosses to the back of the proportioning valve.... however, as the fitting size is different front/rear, it's impossible to screw up from my end. What is odd, in all of that, is the smaller line feeding the front calipers since there are more pistons in the front than in the rear.

Or I could be complete full of crap.... but everything I've read points to what I just described.

Maybe it's supposed to be square line, and Chad will write an article about how it's stupid to have round line....

I think someone made a mistake at SS brakes because the front line/rear line orientation on a C3 is reversed of what is "normal." Normally, the front reservoir feeds the front brakes, and the rear the rear brakes; but on a true C3 Master cylinder the line from the front then crosses to the back of the proportioning valve.... however, as the fitting size is different front/rear, it's impossible to screw up from my end. What is odd, in all of that, is the smaller line feeding the front calipers since there are more pistons in the front than in the rear.

Or I could be complete full of crap.... but everything I've read points to what I just described.

Maybe it's supposed to be square line, and Chad will write an article about how it's stupid to have round line....

Comment