heh, Toyota seat-builders were probably moonlighting doing those chairs

so, progress?

now it's as far apart as I'm going to take it (which is good since there isn't anything left to remove)

Buick thinks the old-school sbc is a good choice

on the trailer for a trip to the sand blaster

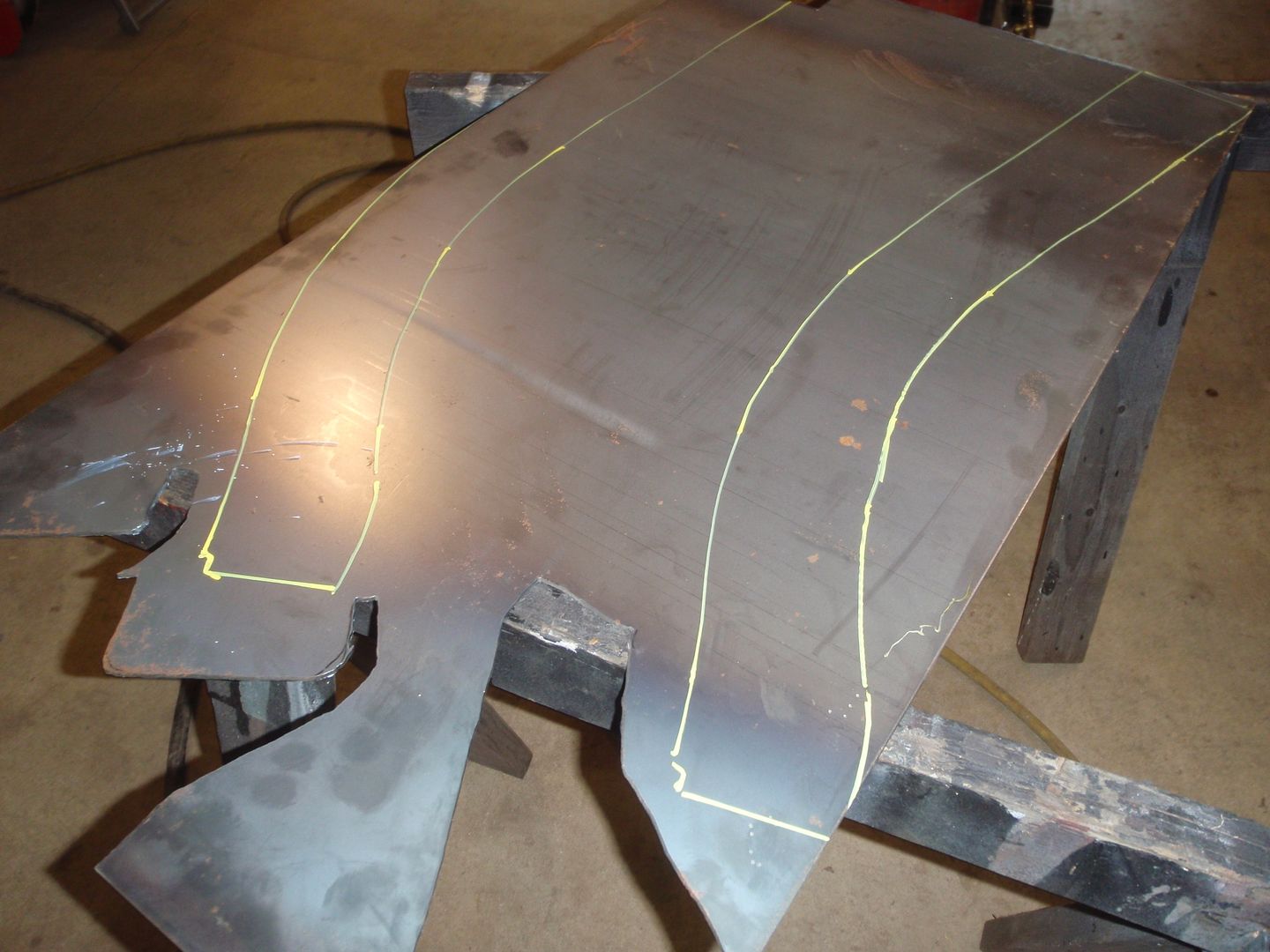

and back to the driver's seat frame.... I still don't know what I'm going to do

so, progress?

now it's as far apart as I'm going to take it (which is good since there isn't anything left to remove)

Buick thinks the old-school sbc is a good choice

on the trailer for a trip to the sand blaster

and back to the driver's seat frame.... I still don't know what I'm going to do

Comment