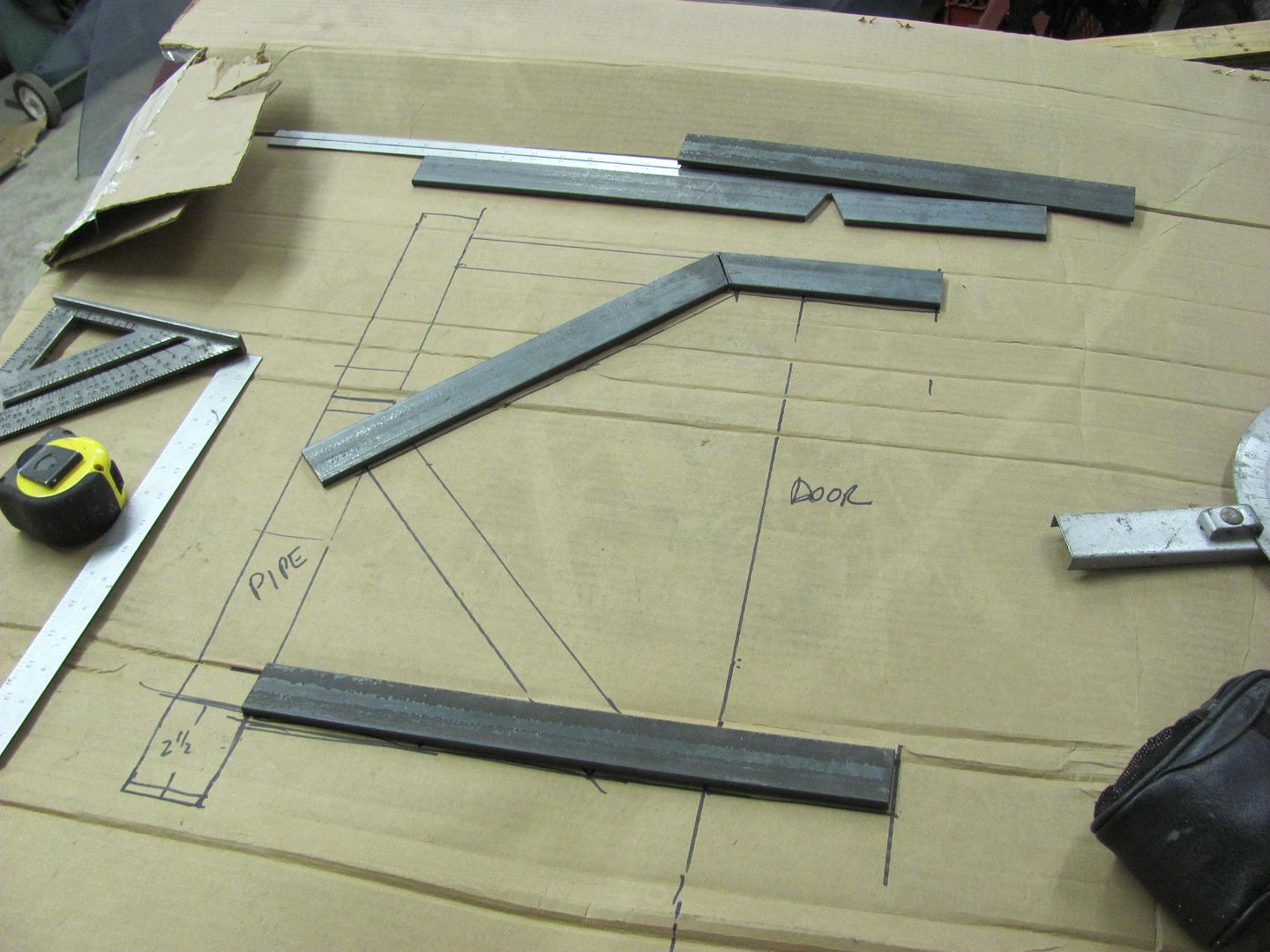

While Kyle continued media blasting fenders, I worked on closed up a gaping hole....

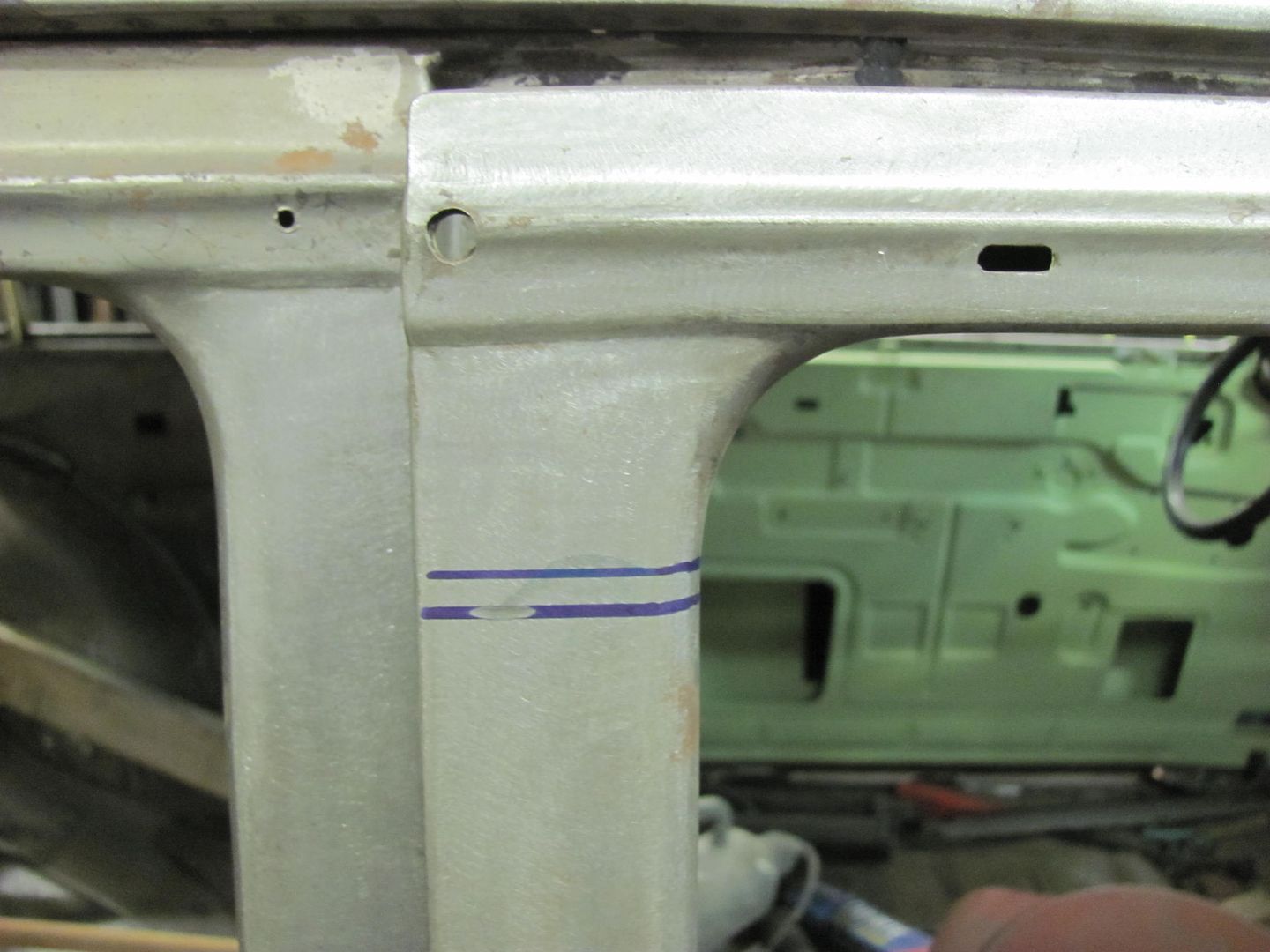

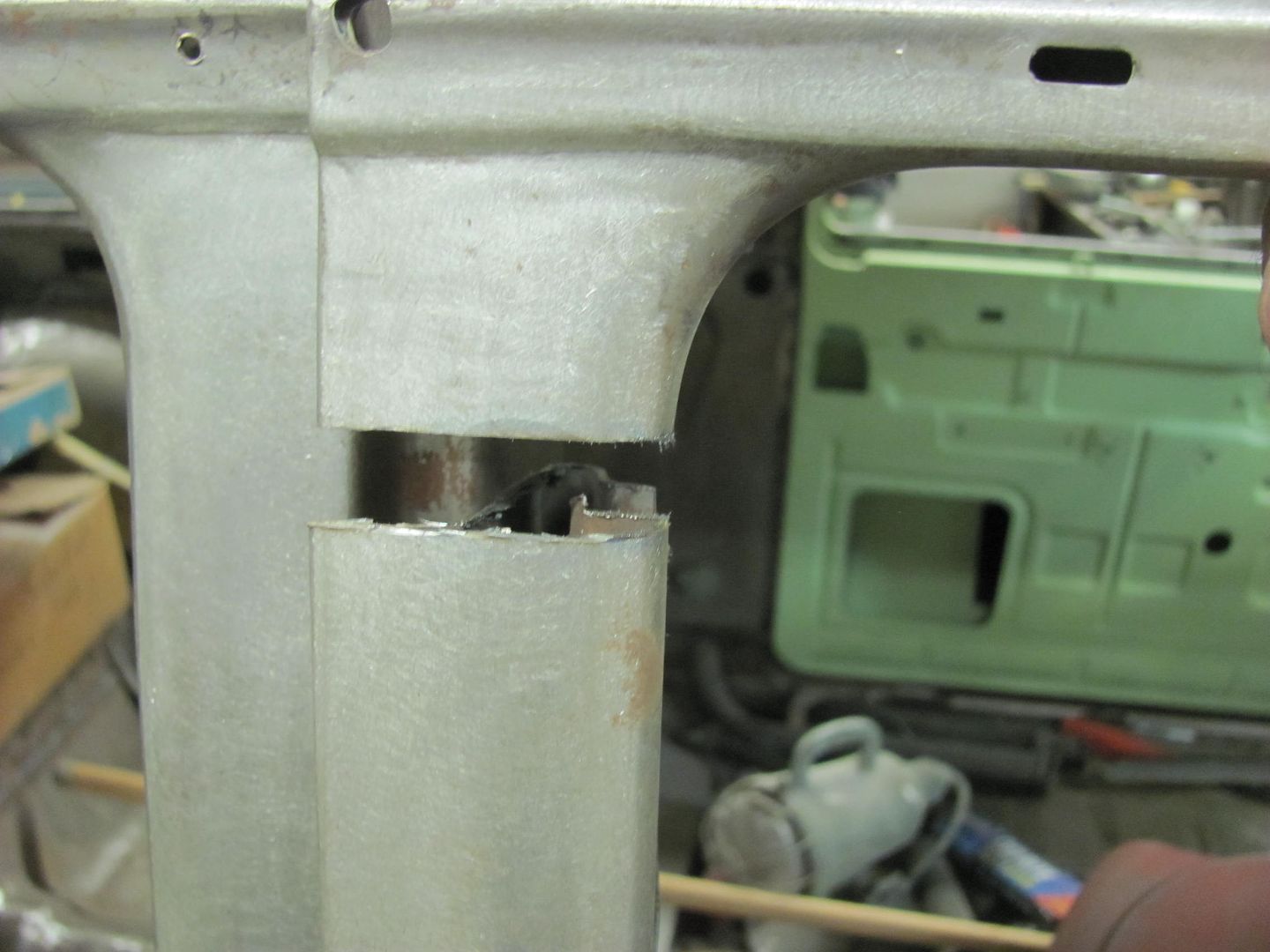

A couple weak spots dictated a bigger hole. Here the radius was added from the A pillar to beneath the drip rail..

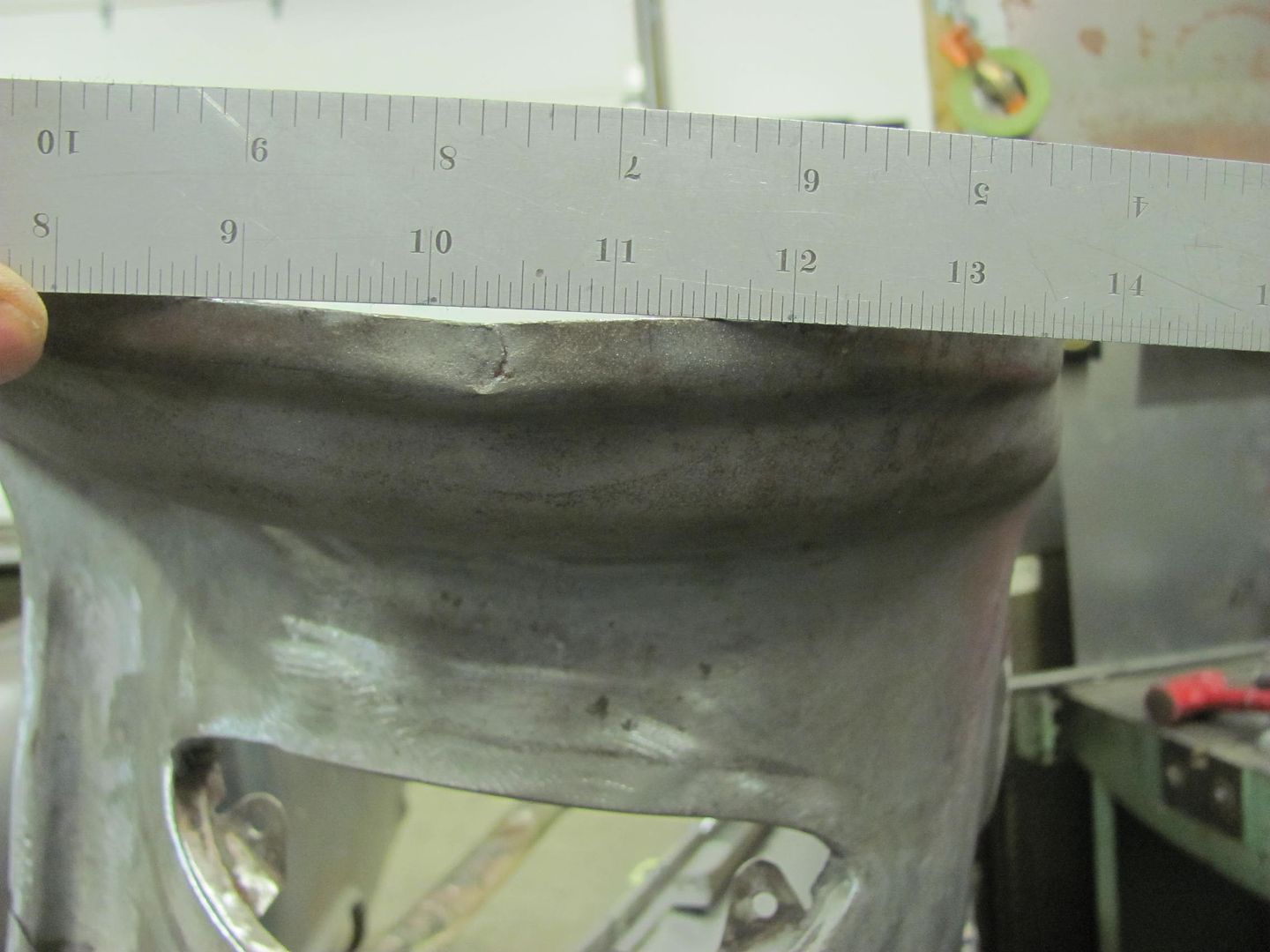

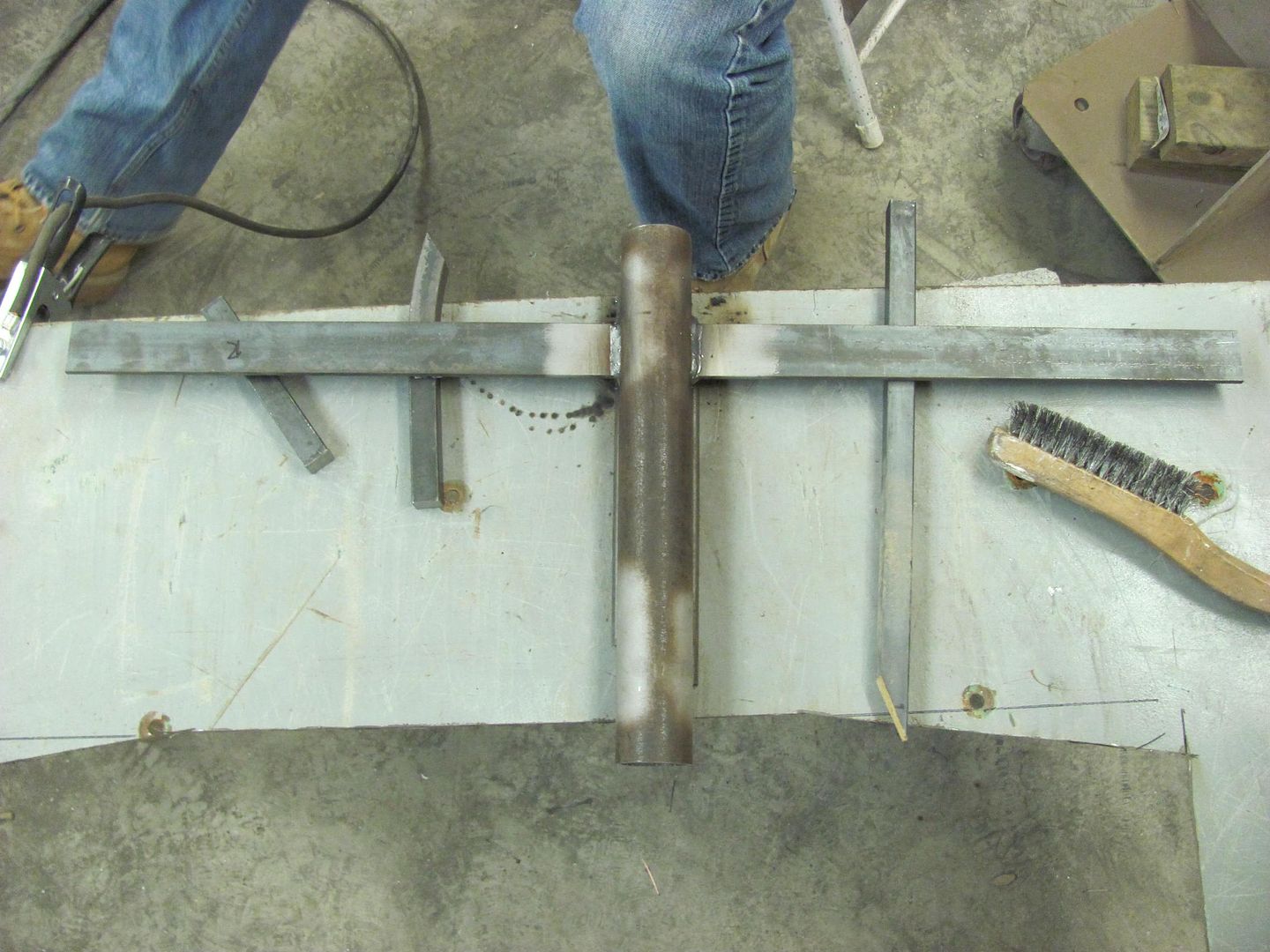

Test fit

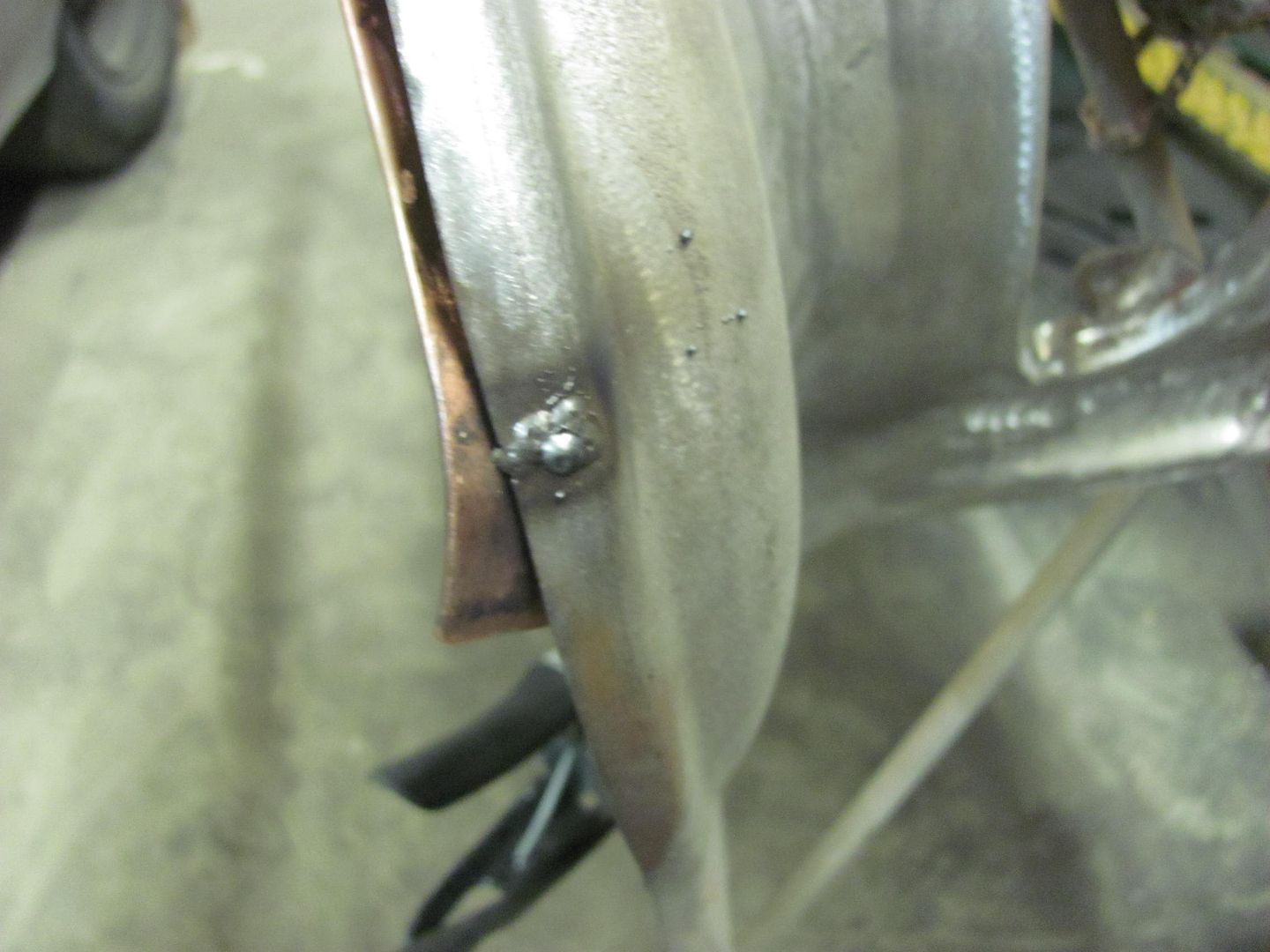

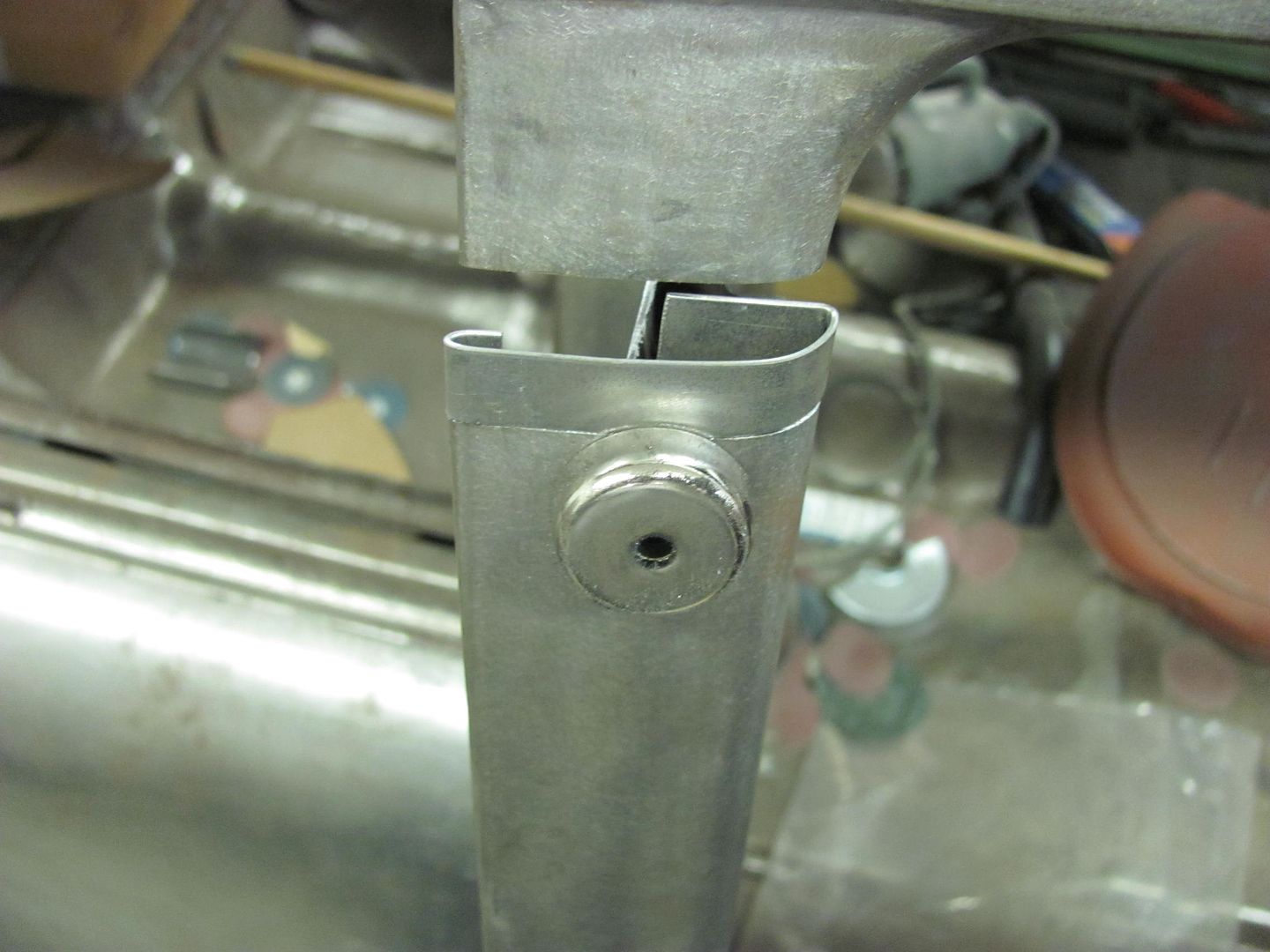

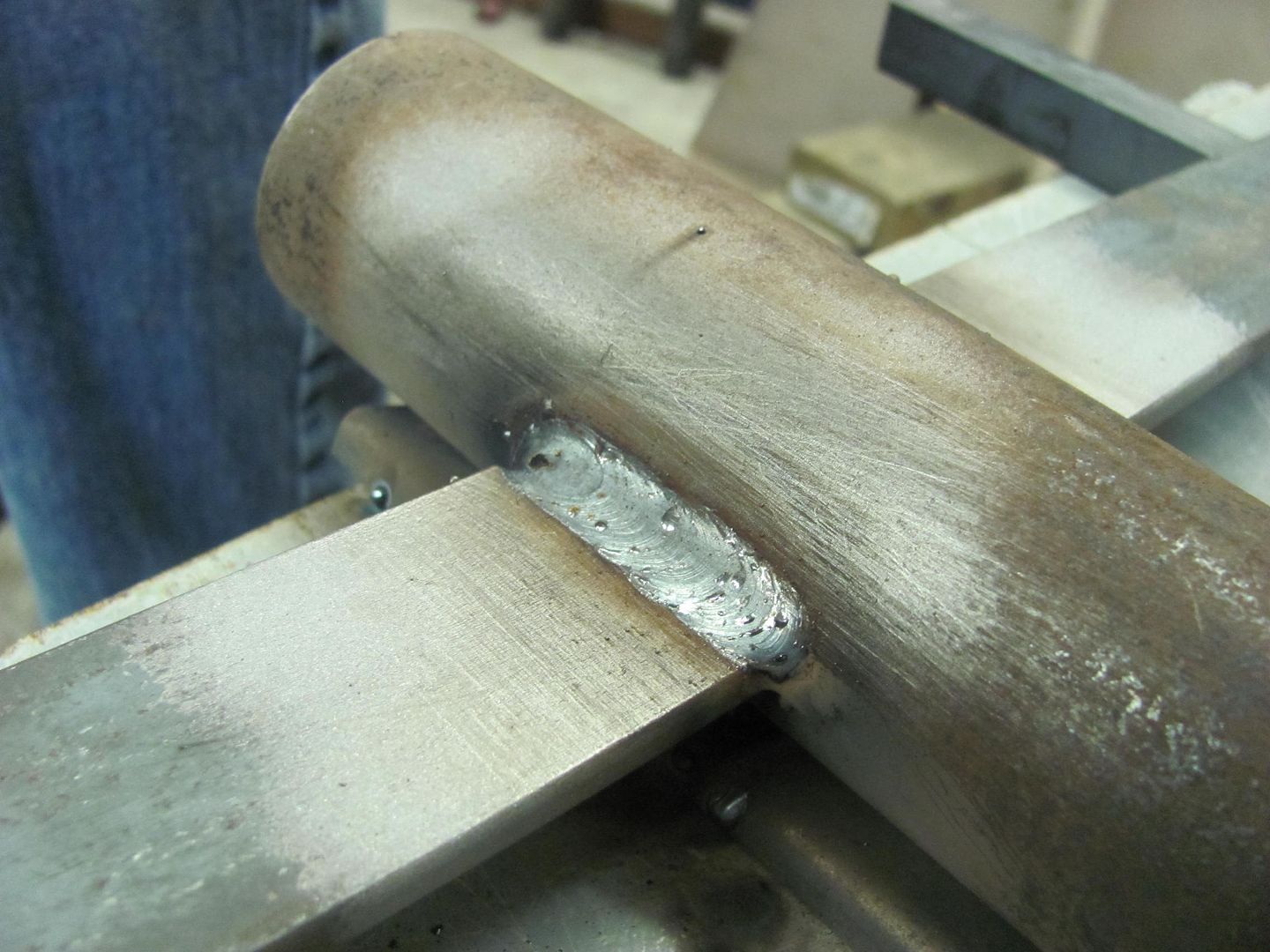

Welded in place.....

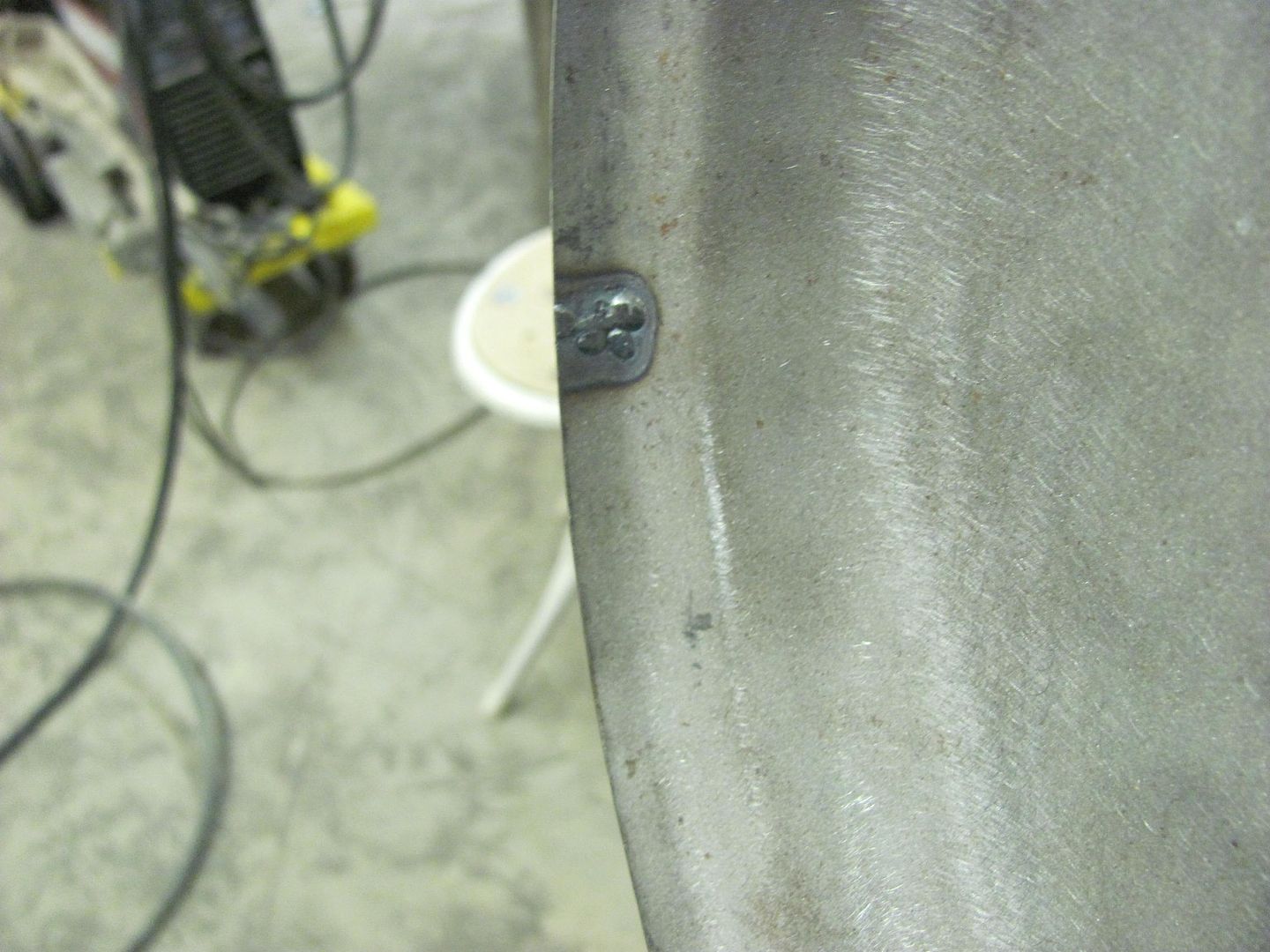

Used a torch and wire brush to clean off the other side, looks like this gap was a factory deal, and we have another radius to install..

A couple weak spots dictated a bigger hole. Here the radius was added from the A pillar to beneath the drip rail..

Test fit

Welded in place.....

Used a torch and wire brush to clean off the other side, looks like this gap was a factory deal, and we have another radius to install..

Comment