Dan, I think she's about 5'8 or so..

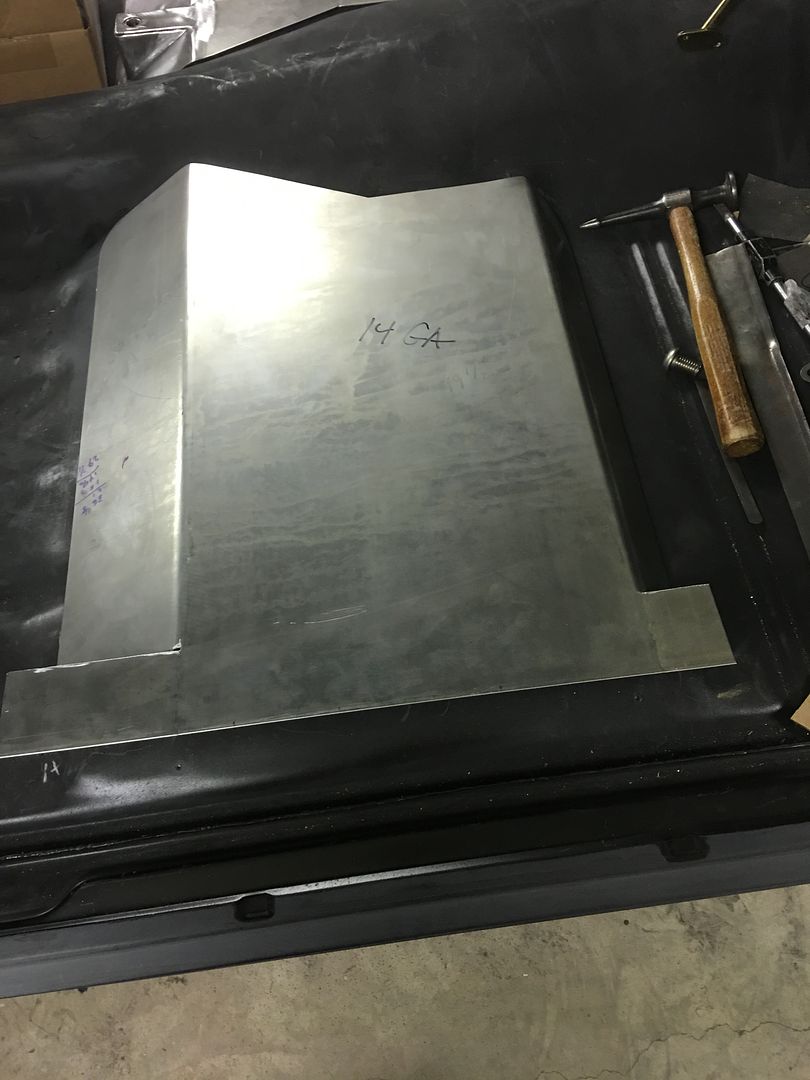

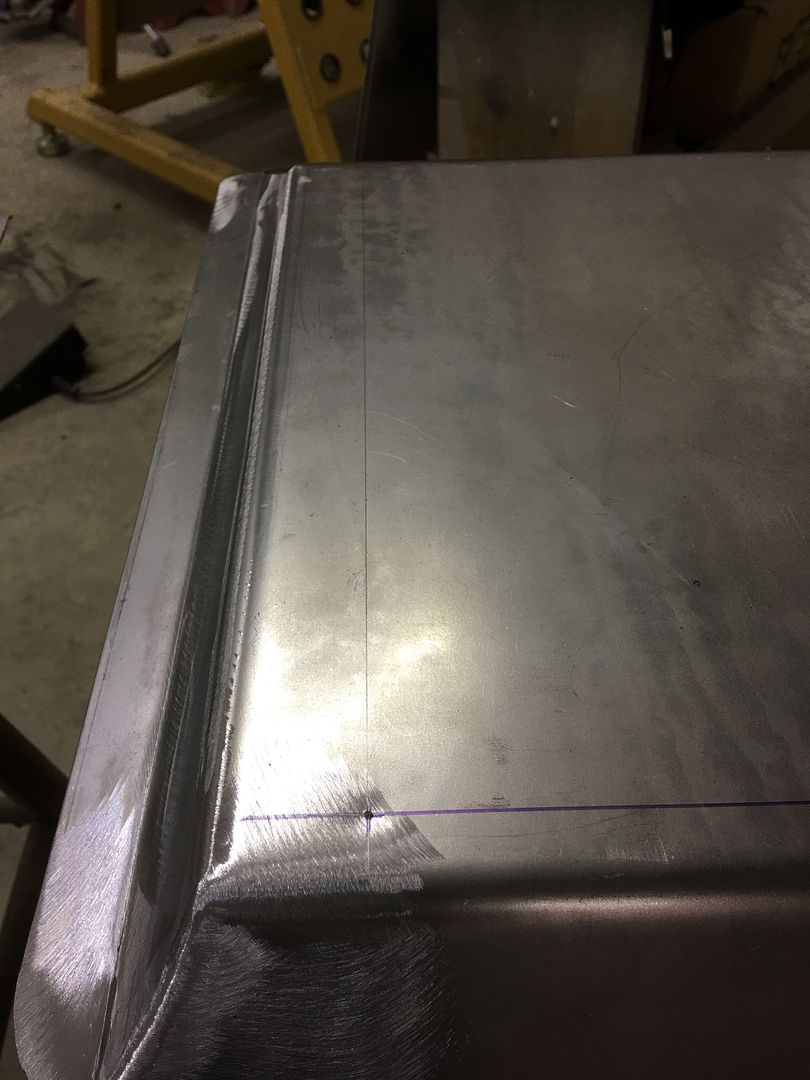

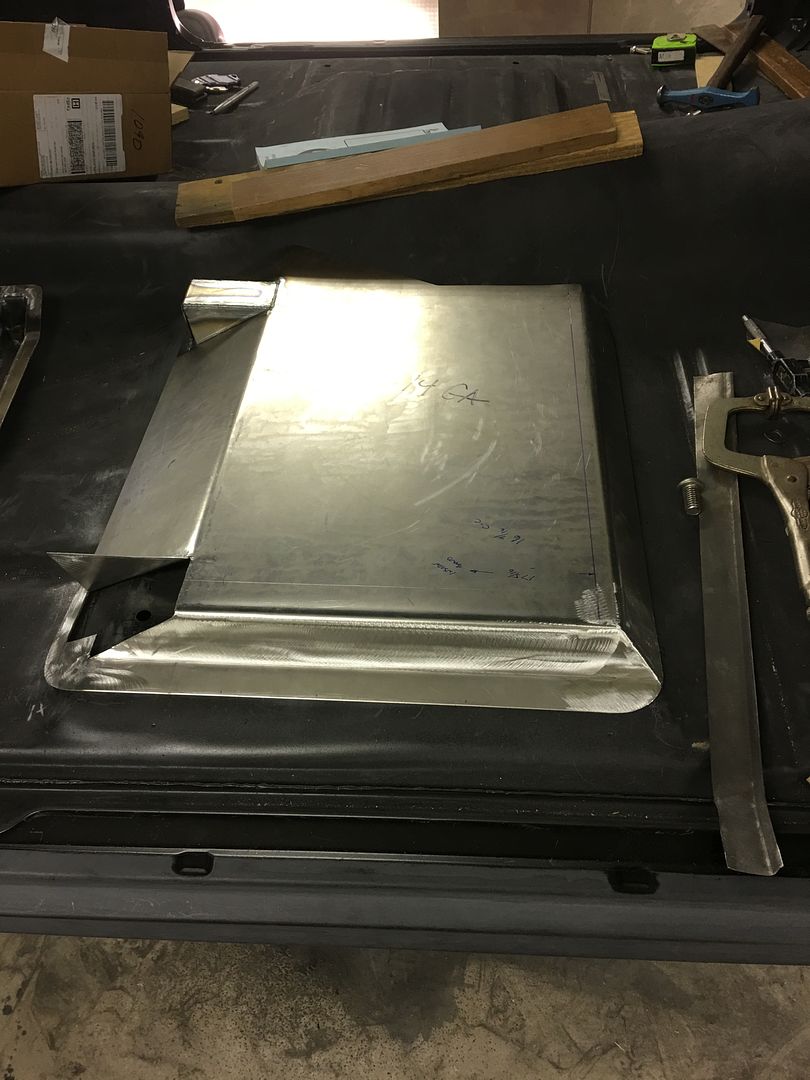

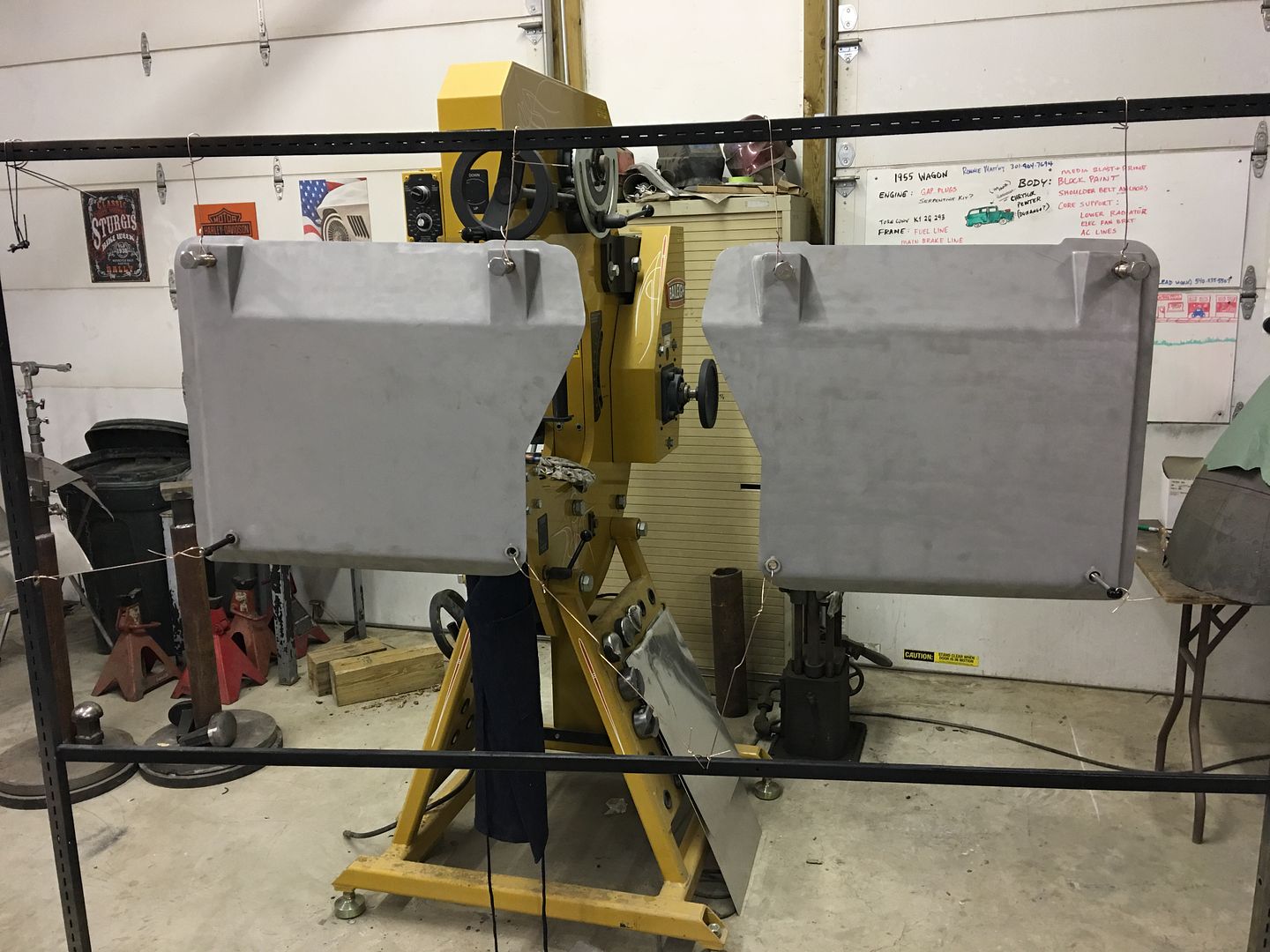

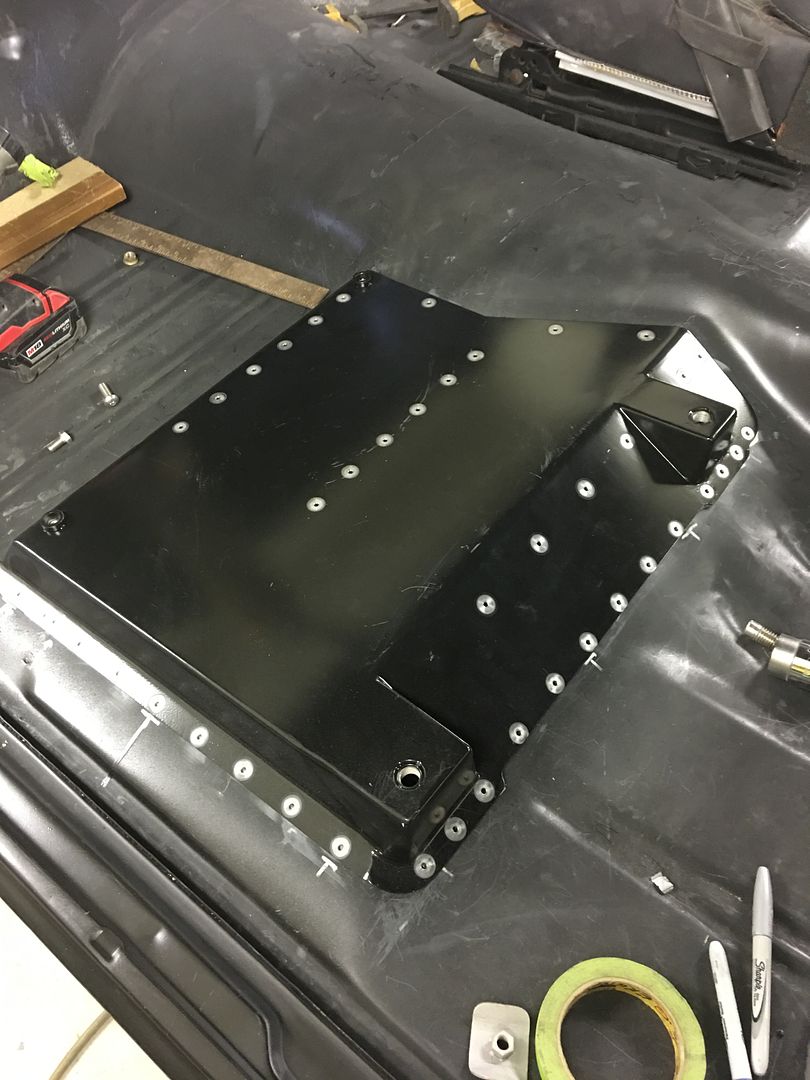

Final design on the bucket seat brackets... and owner approved today as well. One down, one to go.. This is made from 14 gauge cold rolled steel and puts the seat about as low as we can go without cutting the floor pan..

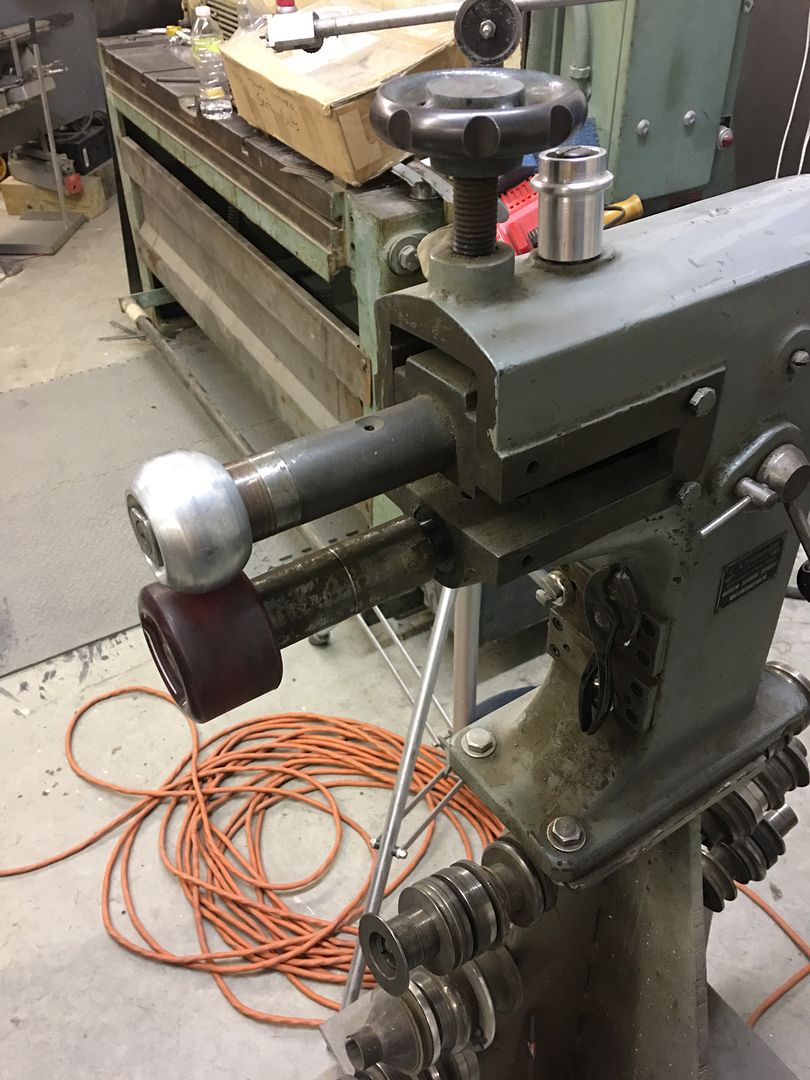

Video of the seat bracket:

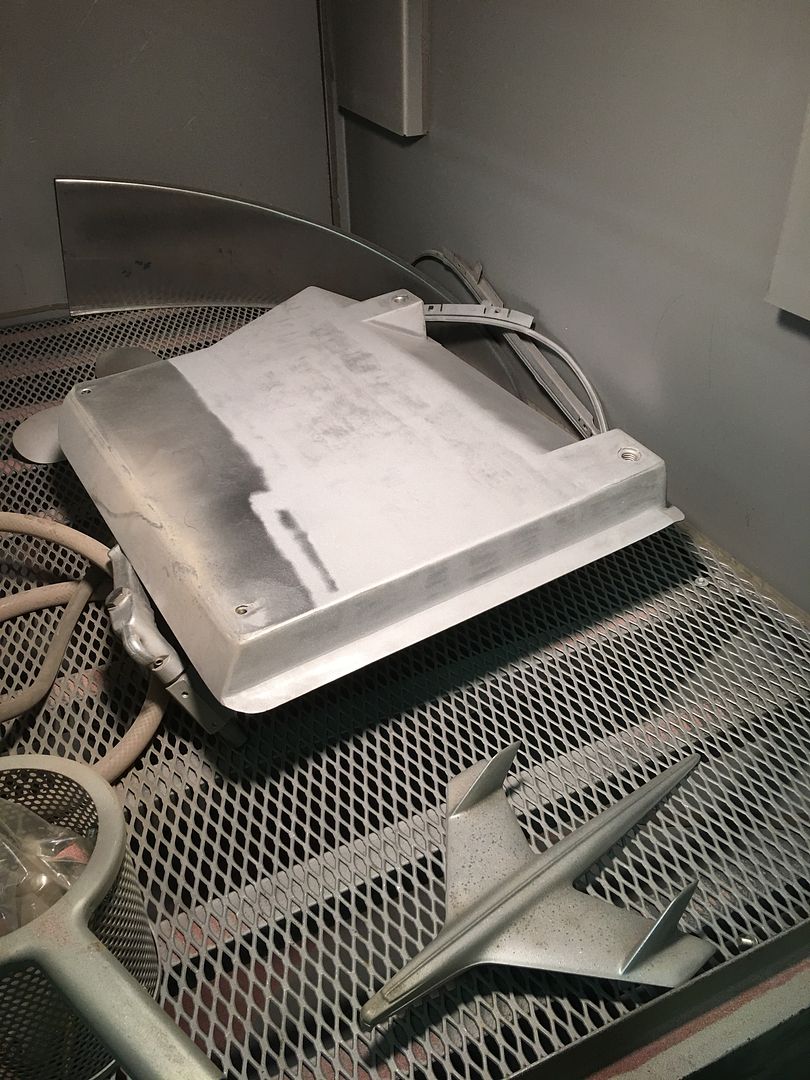

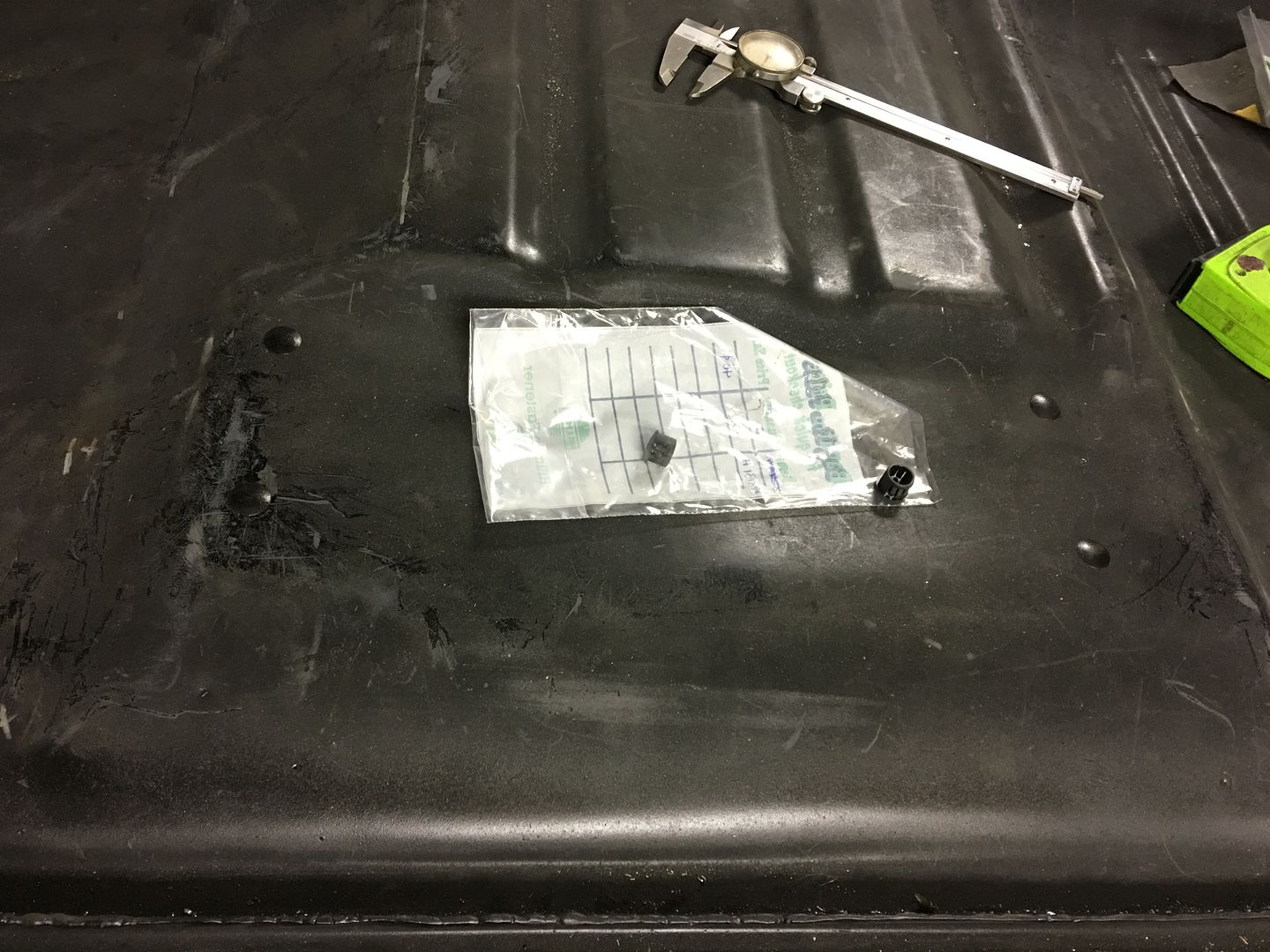

Seat test fitted:

Final design on the bucket seat brackets... and owner approved today as well. One down, one to go.. This is made from 14 gauge cold rolled steel and puts the seat about as low as we can go without cutting the floor pan..

Video of the seat bracket:

Seat test fitted:

....

....

Comment