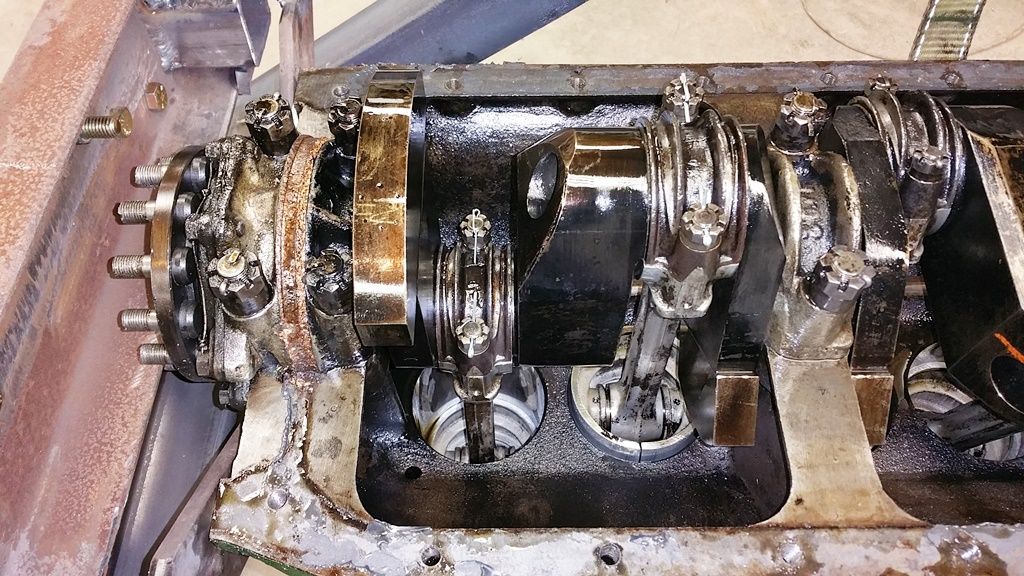

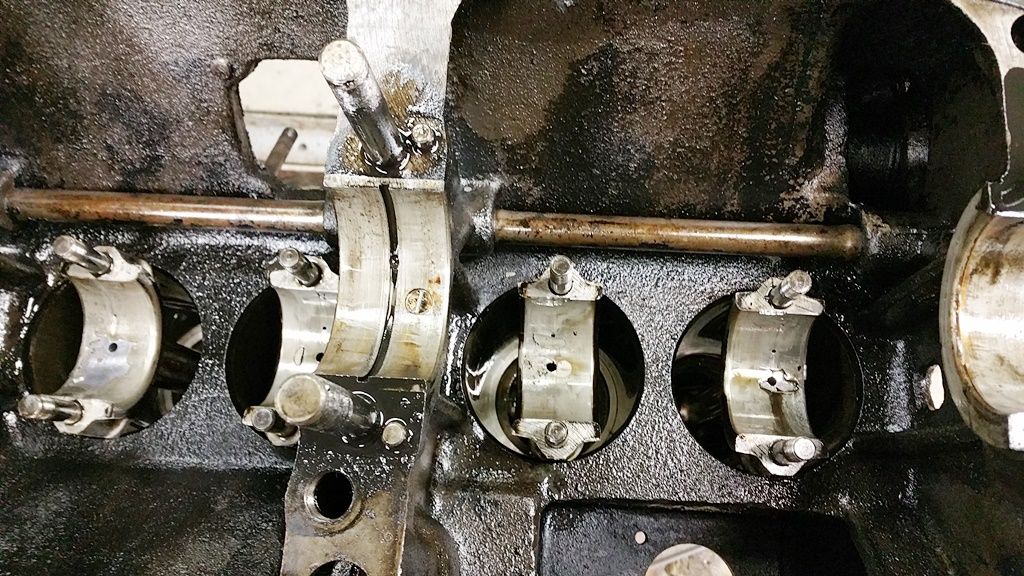

About 3 years ago I pulled the oil pan off of the 29 Duesenberg, mostly out of curiosity. I found that the original aluminum rods were losing some of the poured in place babbit bearing material, thus I have seldom driven the car since. Well, it has been announced that there will be a Duesenberg Drag Race this coming Labor day weekend, and they are trying to set a new record for Duesenberg attendance. That motivated me to get busy on this car so I can make the event. So now I am trying to finish my 31 Plymouth hot rod for Drag Week 2015, and simultaneously rebuilding the mighty 420 inch Straight Eight. That doesn't leave me much time to play on the web, but I find this project so intriguing, I want to share it with my fellow Bangshifters.

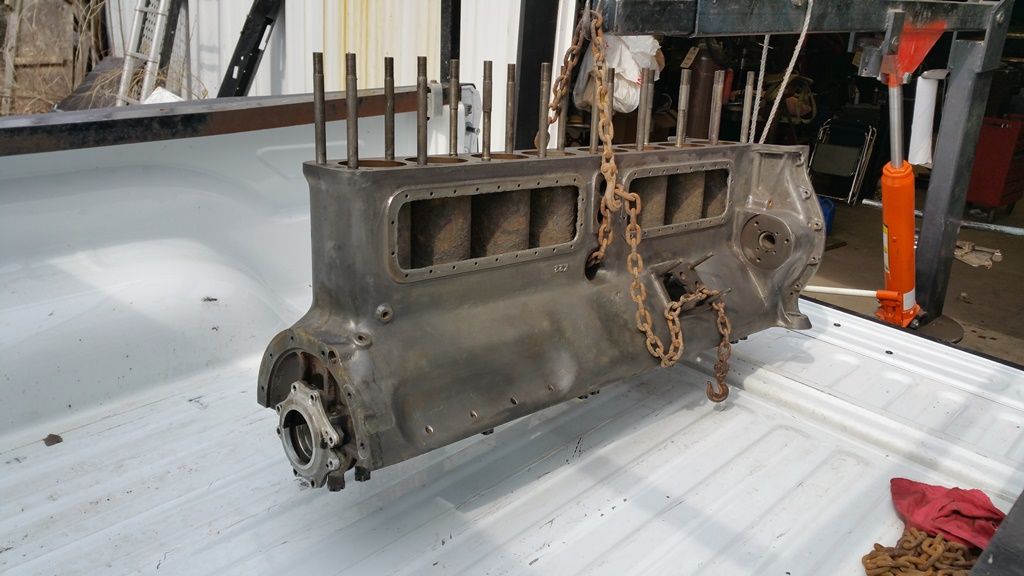

Here is a shot of the car, and the engine prior to the start of the project:

I did all the usual disconnecting type stuff, but spend WAY more time and care than usual documenting, to aide in proper re-assembly. I removed the head, trans, clutch and flywheel prior to pulling this big beast.

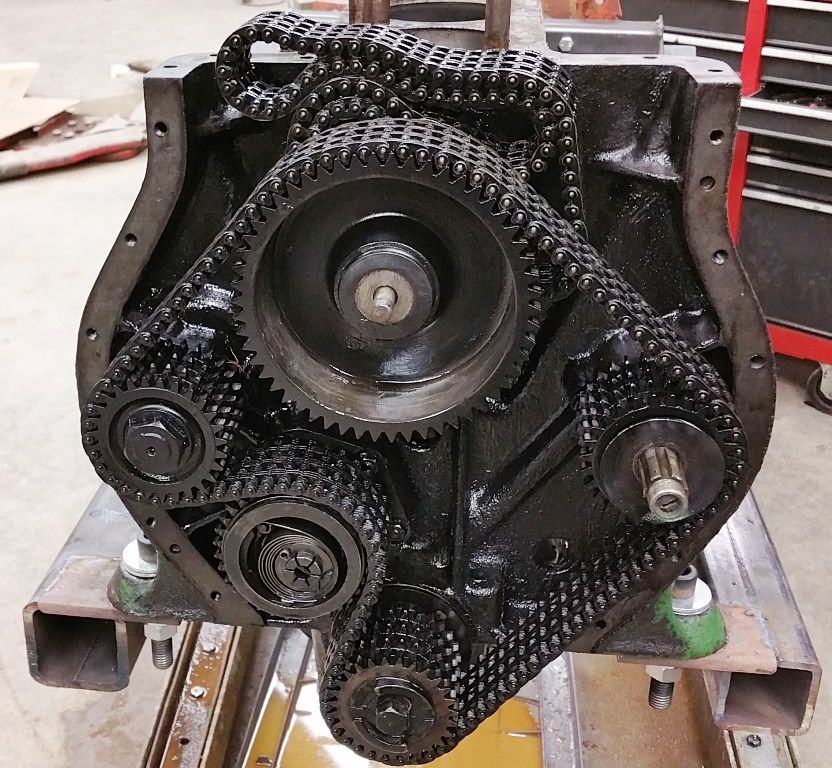

Cam covers and intake removed:

I beefed up my cherry picker a bit before pulling:

There was a lot of rusty sludge under the water jacket covers, so I put the covers back on and soaked it with evaporust, which eliminated the rust, but is not acidic.

Here is a shot of the car, and the engine prior to the start of the project:

I did all the usual disconnecting type stuff, but spend WAY more time and care than usual documenting, to aide in proper re-assembly. I removed the head, trans, clutch and flywheel prior to pulling this big beast.

Cam covers and intake removed:

I beefed up my cherry picker a bit before pulling:

There was a lot of rusty sludge under the water jacket covers, so I put the covers back on and soaked it with evaporust, which eliminated the rust, but is not acidic.

Comment