Originally posted by DanStokes

View Post

Announcement

Collapse

No announcement yet.

RideTech 48 Hour Corvette Build

Collapse

X

-

Originally posted by RideTech_Ryan View Post

I am not certain what you mean on the rear steer term. The C3 is a rear steer car and with our kit we eliminate bump steer. We created a rear mounting coilover for stability and ease of access. We did not use a jeep box on any of our cars, we used the Borgeson box. The Borgeson box allows for quicker turning and no sacrifice to your turning radius. We don't plan to change the rear kit. Through out testing the rear Strong Arm kit performs extremely well. We did design the rear trailing arms to allow the fitment of larger aftermarket half shafts as well. When you are talking about the car unloading in a corner what i believe you are feeling is bump steer.

I hope this answers your questions!

it does - the weakness inherent in the C3 design is the c-clip that holds the driveshaft to the spindles. Bigger, stickier tires and autocross g-forces are not conducive to wear and breakage issues. What really got me thinking about your system was your picture of the C3 rear end with the lighter-duty spud shafts

no one else in the market solves this problem - so I don't really see it as a detriment (merely a "use the Viper center section and a Guldstrand 6 link update" if you have troubles).

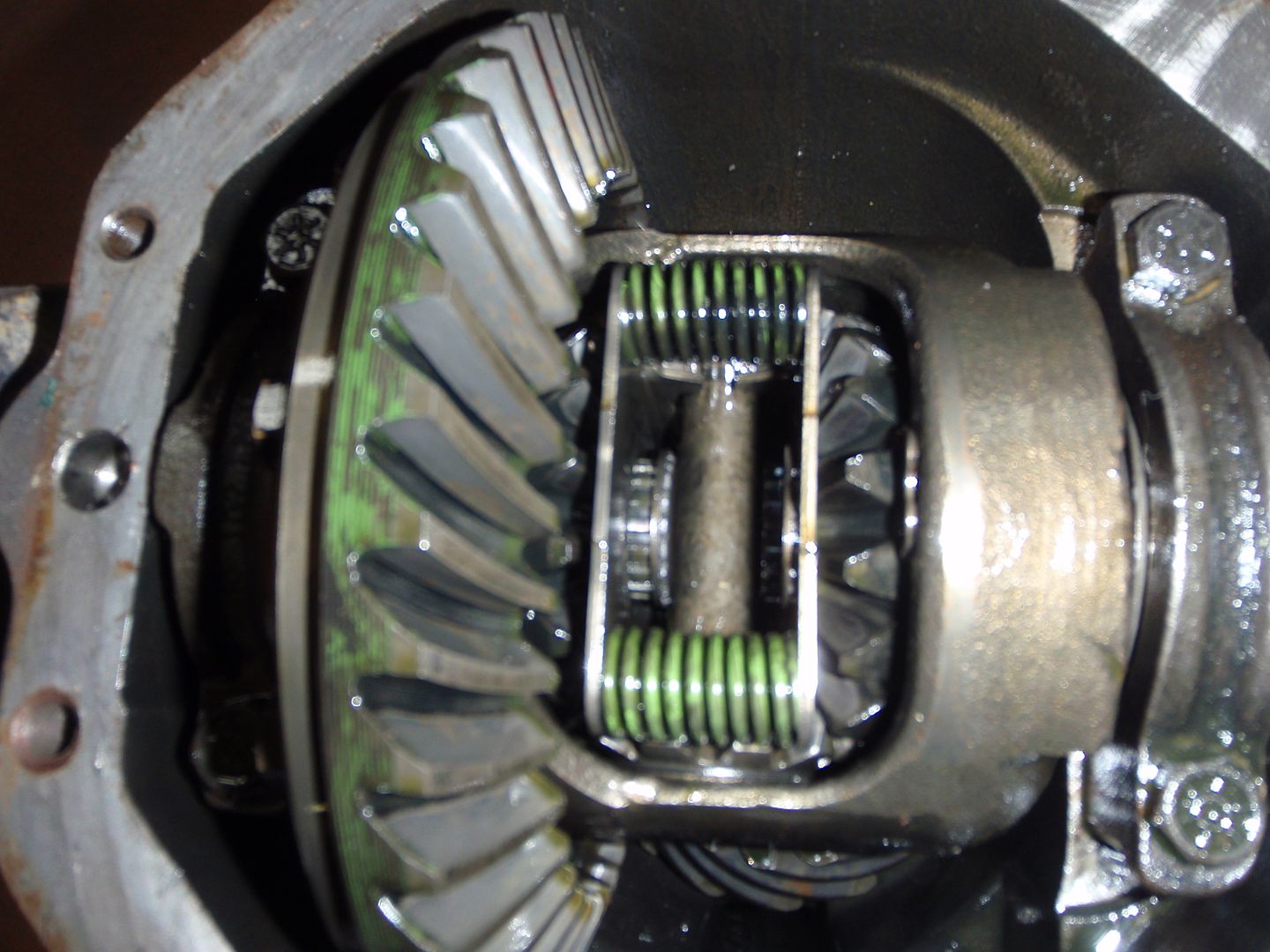

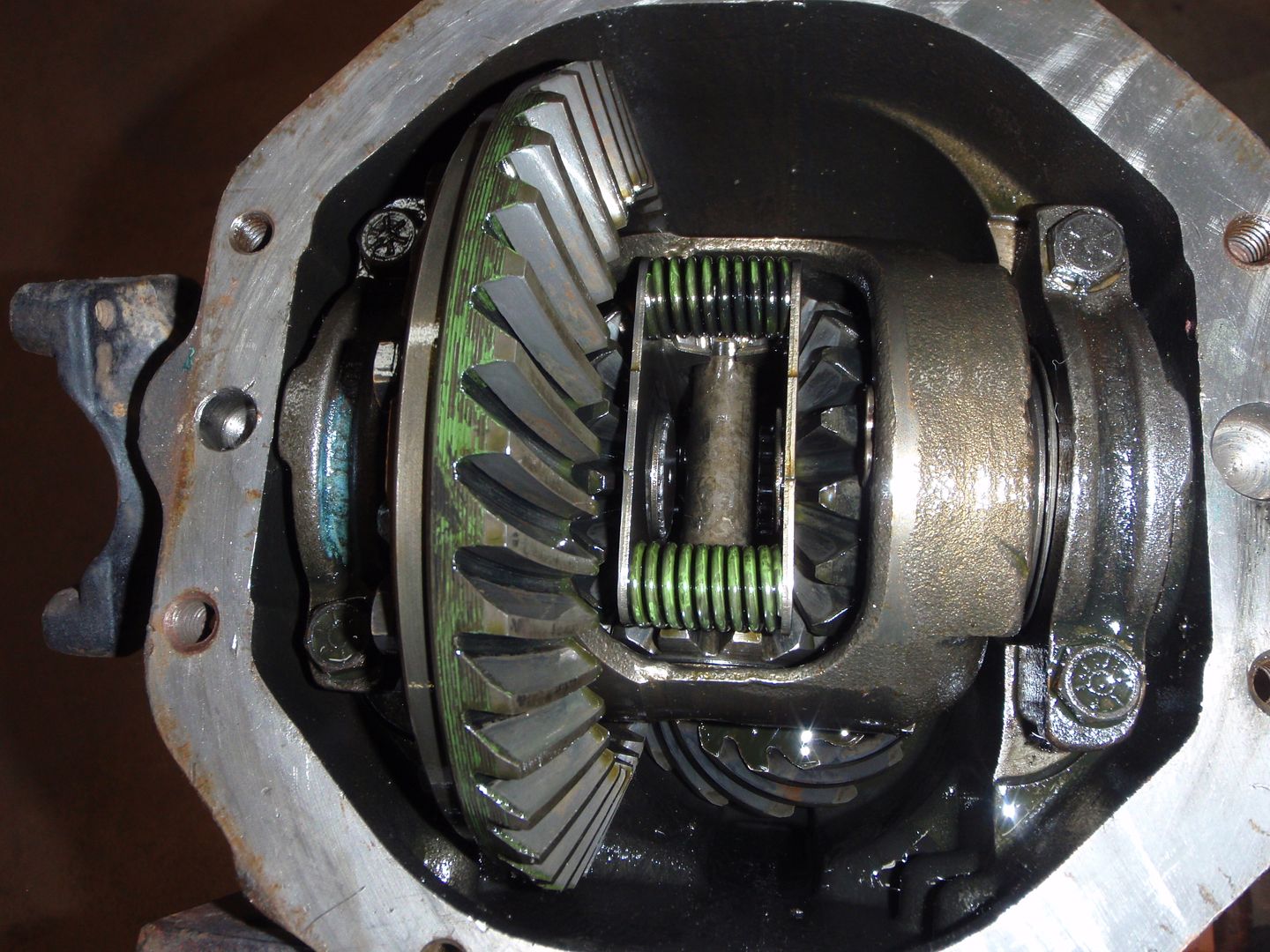

here's some pictures of inside my differential

if you look at the left side spud shaft, you'll see what happens when the shaft wears. GM only hardened the end of the shaft, thus, the rubbing the shaft gets on the center pin wears the material down to the point you get movement of the shaft.... your kit, while quite impressive, is going to cause even more troubles with wear at this point. I'm certainly not telling you what to do, but I'm also saying perhaps you should consider solutions for when people call in and complain that their rear suspension is acting strange... this amount of play, almost put me into a ditch because of that rear-steering issue. Also, consider this - that little, tiny c-clip is what keeps the shaft in the differential

Bump steer can be part of what is going on, but you don't need a bump to get unpredictable steering - and that's why I'm reluctant to agree that it's a bump steer issue... the rear arm travels in 2 planes, thus, as the tire goes up and down in the wheel well, the rear arm pulls the front of the tire towards the center of the car - but it does so in a non-linear manner... most drivers, once they're used to it, can drive around the problem; but to anyone who's used to a solid rear axle - the initial learning curve is a bit.. well... entertaining. On VetteMod, there's quite a number of discussions about the issue and the various attempts at solutions...Last edited by SuperBuickGuy; March 4, 2015, 08:17 AM.Doing it all wrong since 1966

Comment

-

there are band-aids.

first, there is the guldstrand set up that removes the c-clip, machines (read, grinding wheel) the shaft down to the c-clip, then puts an upper arm from the top of the differential to the arm. The issue with the guldstrand set up is it also changes the control arm to a dual set-up like the C4 corvette... more pivot points means more wear. On a race car, that's not a big deal; but a street car - it's noisy and a severe service item. The other issue is the differential seal wasn't designed to allow in and out motion - thus it will wear out pretty quickly. Finally, there's an angle problem that it's putting a load in a direction that isn't terribly strong.

The solution to that is to put slip joints on each driveshaft... of course, that's more weight and complexity

The other solution is to use a Viper center section - and replace the u-joints with CV joints.... that issue is you're on your own for the wheel-end of the shaft. I think that if someone came up with CV joints for both ends then put the upper control bar in - that would solve 90% of the problems... of course, someone needs to spend the time engineering that solution.

and who knows, I may do it myself for my car.... but it's not something I'm interested in doing now - I've already too much on my plate.

It's certainly something Ridetech could do - but I'm not them... I'm sure they've bigger fish to fry.... and don't mind me, either, I think their solution is more elegant than the sharkbite system.... of course, it mostly follows what I did to mine, so I might be a bit biased.Last edited by SuperBuickGuy; March 4, 2015, 10:10 AM.Doing it all wrong since 1966

Comment

-

I really don't want (thus this second post) you to think that I dislike your system; it's still a very real consideration for the next C3... but with that said, I challenge you to discuss your system on a place where you'll get solid review by the experts - (not Corvetteforum) - on Vettemod.com

Doing it all wrong since 1966

Comment

-

Ryan -

Hope you tune in tonight or tomorrow -

I have a couple of Shockwave questions. Here's the pics:

Overview of the installation, passenger's side.

Question #1) The 3/8 bolts in the kit are too big to go thru the Shockwave trunion. Should I enlarge the slot in the trunion or go with smaller (8mm or 5/16") hardware? I have it sitting in place by using a couple of 8mm bolts.

Question #2) Should I lube the Delrin top bushings or are they self-lubricating? If they get lube, what should I use?

There's a ridge that runs around the back side of the old spring pocket. There's about 1/2" clearance between it and the air bag and I'm pretty sure it adds considerable strength to the assembly.

Question #3) Is the 1/2" adequate or should I cut that back? The screwdriver is pointing to the ridge in question and there's about the shown clearance all the way around.

Thanks for your input, especially on your weekend.

Dan

Last edited by DanStokes; March 6, 2015, 06:57 PM.

Comment

-

And totally screwed up the build. Notice Hot Rod got their build done on time; only difference between that build and this one was Chad is on this build - his hatred of Corvettes and their owners rubbed off and brought the whole team down. Way to go Chad.... what are we at now, 48 hours plus 4?Last edited by SuperBuickGuy; March 13, 2015, 10:39 AM.Doing it all wrong since 1966

Comment

Comment